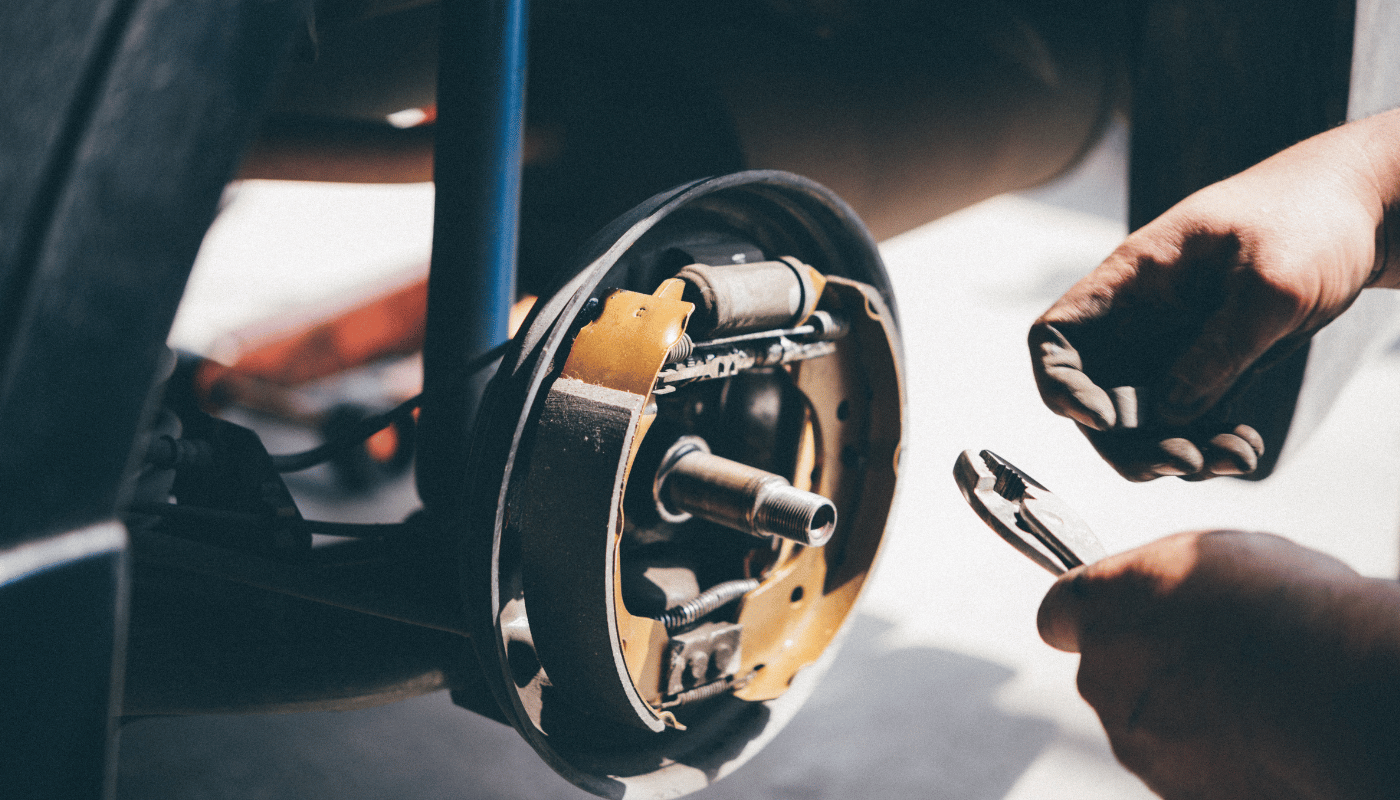

At Iskander Garage, we provide specialized machine services for all types of brake drums and rotors. Our precision machining ensures your braking components perform optimally, enhancing your vehicle’s safety and stopping power. Whether your vehicle uses drum brakes or disc brakes, our expert technicians are equipped to handle all your machining needs.

1. How do I know if my brake drums or rotors need machining?

Signs that your brake drums or rotors may need machining include vibrations or pulsations when braking, visible grooves or scoring, and a squealing noise when applying the brakes. Our technicians can inspect your braking components to determine if machining is necessary.

2. How often should brake drums and rotors be machined?

The frequency of machining depends on driving conditions, brake usage, and the quality of the braking components. It’s recommended to have your brakes inspected regularly, and machining should be considered when there is noticeable wear or performance issues.

3. Can all brake drums and rotors be machined?

Not all brake drums and rotors can be machined. If the components are too worn, warped, or damaged, machining may not be feasible, and replacement may be necessary. Our technicians will assess the condition of your braking components and advise you accordingly.

4. Is machining brake drums and rotors safe?

Yes, machining brake drums and rotors is a safe and effective way to restore their surface and improve braking performance, provided it is done within the manufacturer’s specifications for minimum thickness and safety standards.

5. Do I need an appointment for machining services?

While walk-ins are welcome, we recommend scheduling an appointment to ensure prompt service. You can call us or use our online scheduling tool.

Ultrasonic injector cleaning and pressure testing is a meticulous process aimed at restoring fuel injectors to optimal performance. Here’s an overview of the steps involved:

Assessment: The process begins with a thorough assessment of the fuel injectors to identify any issues or deposits that may be affecting their performance.

Removal: The injectors are carefully removed from the engine to facilitate cleaning and testing.

Cleaning: The injectors are placed in an ultrasonic cleaning tank filled with a specialized cleaning solution. Ultrasonic waves create high-frequency vibrations that dislodge stubborn deposits and contaminants from the injector nozzles, pintle caps, and internal components.

Flushing: After ultrasonic cleaning, the injectors are flushed with clean solvent to remove any remaining debris or cleaning solution.

Inspection: Each injector is visually inspected to ensure that all deposits have been removed and that the internal components are in good condition.

Pressure Testing: The injectors undergo pressure testing to evaluate their spray pattern, flow rate, and sealing integrity. This helps identify any issues such as leaks or irregularities in fuel delivery.

Reassembly: Once cleaned and tested, the injectors are reassembled with new seals, O-rings, and filters as needed.

Reinstallation: The restored injectors are reinstalled in the engine, ensuring proper seating and connection to the fuel rail and fuel lines.

Final Testing: The engine is started, and the fuel system is checked for proper operation and performance. Any remaining issues are addressed before the vehicle is returned to the customer.

By following these steps, ultrasonic injector cleaning and pressure testing help improve fuel efficiency, engine performance, and overall drivability. It’s a valuable maintenance procedure for keeping your vehicle running smoothly and reliably.

AC diagnostics and leak test, AC gas refill, AC compressor repair, Full AC system flushing service

Premium oil change, Oil filter change, Oil flushing, 360-degree health check

Computerised battery tests,Car battery services,Battery cable tests, Comprehensive electrical check

Transmission inspection, programming, oil, filter services,Gearbox overhauling

Breakdown recovery

Flat tyre recovery

Flat battery recovery

All types of roadside assistance

Engine tuning

Engine detailing

Engine diagnosis

Complete engine overhaul

Engine diagnostics Gearbox Advanced diagnostics State-of-the-art scanning facilities

General car maintenance Basic, Full, & Major services Auto mechanical & electrical Fuel injection & cleaning services

General car maintenance

Basic, Full, & Major services

Auto mechanical & electrical

Fuel injection & cleaning services

Jump-starting

Battery replacement

Testing and diagnostics

On-site service

Towing

Removal of damaged windshield Installation, Sealant application Cleanup

Removal of old timing belt

Installation of new timing belt

Repairing Belt

Color matching service

Fleet branding solutions

Logo integration

Removal of damaged body parts

Installation of new body panels

Alignment, Paint

Surface preparation

Masking and protection

Painting or powder coating

Clear coat application

Visual inspection, Ultrasonic cleaning, Flow testing, Replacement of components (seals, o-rings, filters), Injector calibration

Final inspection and testing

Evacuation of refrigerant Accessing the evaporator unit Disconnection of refrigerant lines and electrical connectors Replacement of the evaporator unit Reconnection of refrigerant lines and electrical connectors

Iskander Garage offers professional tire alignment services to ensure your vehicle's wheels are properly aligned. Proper alignment helps extend tire life, improve vehicle handling, and increase fuel efficiency.

©2019.Iskander Garage All Rights Reserved.

©2019.Iskander Garage All Rights Reserved.